A Recognized Leader in Fast Ship Propeller Manufacturing

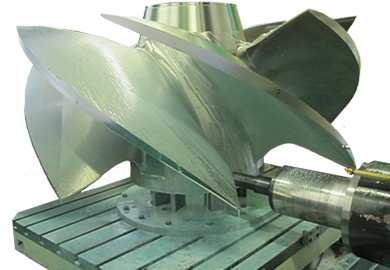

Dominis was founded in 1985 with a vision to build high-precision propellers that reduce noise, vibrations and increase fuel efficiency. By the late 1990’s, the company developed Dominis IPMS (Integrated Propeller Manufacturing System), a manufacturing system, based on a state-of-the-art technology which allows us to CNC (Computer Numerically Controlled) mill large sculptured surfaces such as propellers and water jet impeller to “final form and finish”.

Our monoblock propellers, CP propeller blades and water jet impellers have been used on Canadian and US Navy and Coast Guard vessels. We are constantly improving our processes, tooling and CAD/CAM programming. At Dominis, we are proud to have completely eliminated hand grinding from the manufacturing process of propellers and water jet impellers. Dominis is a recognized leader in ship propeller manufacturing. We specialize in designing and manufacturing precision propellers and water jet impellers for high speed vessels.

FEATURED PRODUCTS

FEATURED CLIENTS

WHY CHOOSE DOMINIS

CNC Milling

Our propellers and impellers are CNC milled to “final form and finish” (No robotic or hand grinding).

Advanced Technology

Dominis has spearheaded research into the impact of manufacturing tolerances on propeller performance.

Decades of Professional Experience

We’ve been machining propellers for naval and coast guard vessels since the mid 1990’s.

Superior Precision

Dominis propellers are up to three times more accurate than ISO 484 Class “S” tolerances.

Improved Performance

Dominis manufacturing processes are designed to reduce propeller noise and vibration.

Service

We work closely with ship builders to achieve their performance requirements.